GE Aviation Engine Testing, Research and Development Centre

- Client: StandardAero Ltd.

- Location: Winnipeg, Manitoba

- Market: Industrial

-

Services & Expertise:

-

Awards:

-

Award of Excellence – Association of Consulting Engineering Companies (Manitoba)

-

New aircraft engine designs must be tested to confirm they can survive real world hazards such as icing, bird ingestion and loss of an engine blade. To construct a state-of-the-art jet engine certification test centre in Winnipeg, General Electric Aviation formed a partnership with StandardAero, who engaged a diversified project team to provide engineering design services.

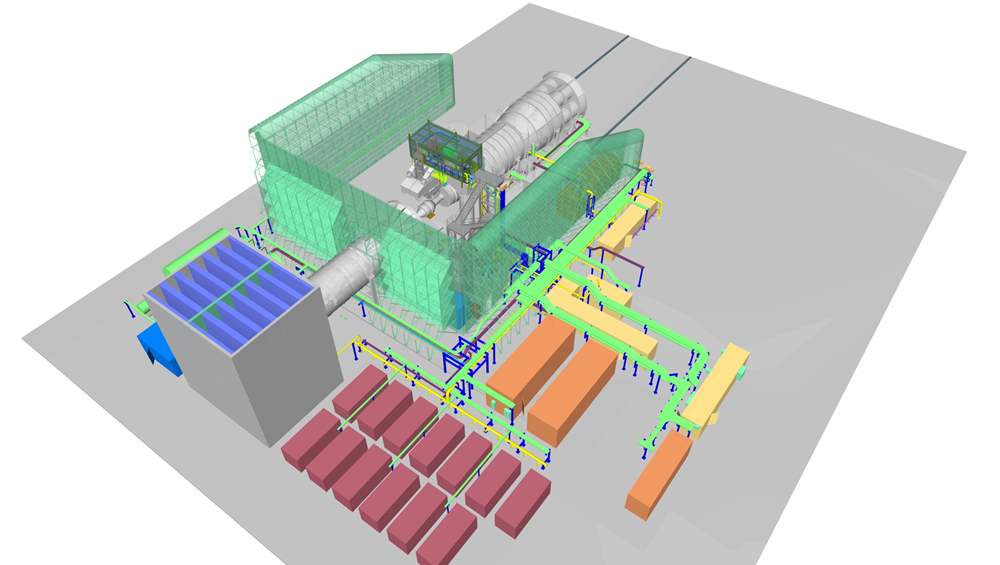

As part of the team, KGS Group coordinated and developed a 3D model of the facility in order to fast track the design and construction. The 3D model required collaborative coordination from our mechanical, electrical and structural groups, importing 3D components created by StandardAero and GE’s engine models, as well as generating 3D models based on 2D design drawings from other consultants. In addition, KGS Group provided design services for various mechanical, electrical and structural aspects of the project.

This project embodies engineering achievement through exemplary project coordination and collaboration to deliver a complex project on time and on budget. The use of innovative technology and a diverse range of engineering expertise were paramount to its success.